Order picking refers to an operation in which items are retrieved from their storage locations to fulfil customer orders. Order picking has also been identified as a major activity within a warehouse and it consumes about 55% of total warehouse operating costs.

Pickers spend about 55% to 70% of time travelling during order picking.

There are a number of order picking systems currently used in warehouses. Generally, the methods are classified following:

who picks the orders (humans or machines) and

who moves (picker or products)

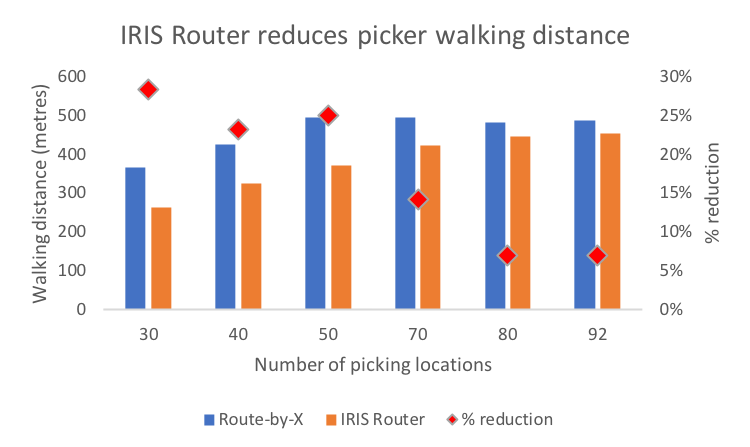

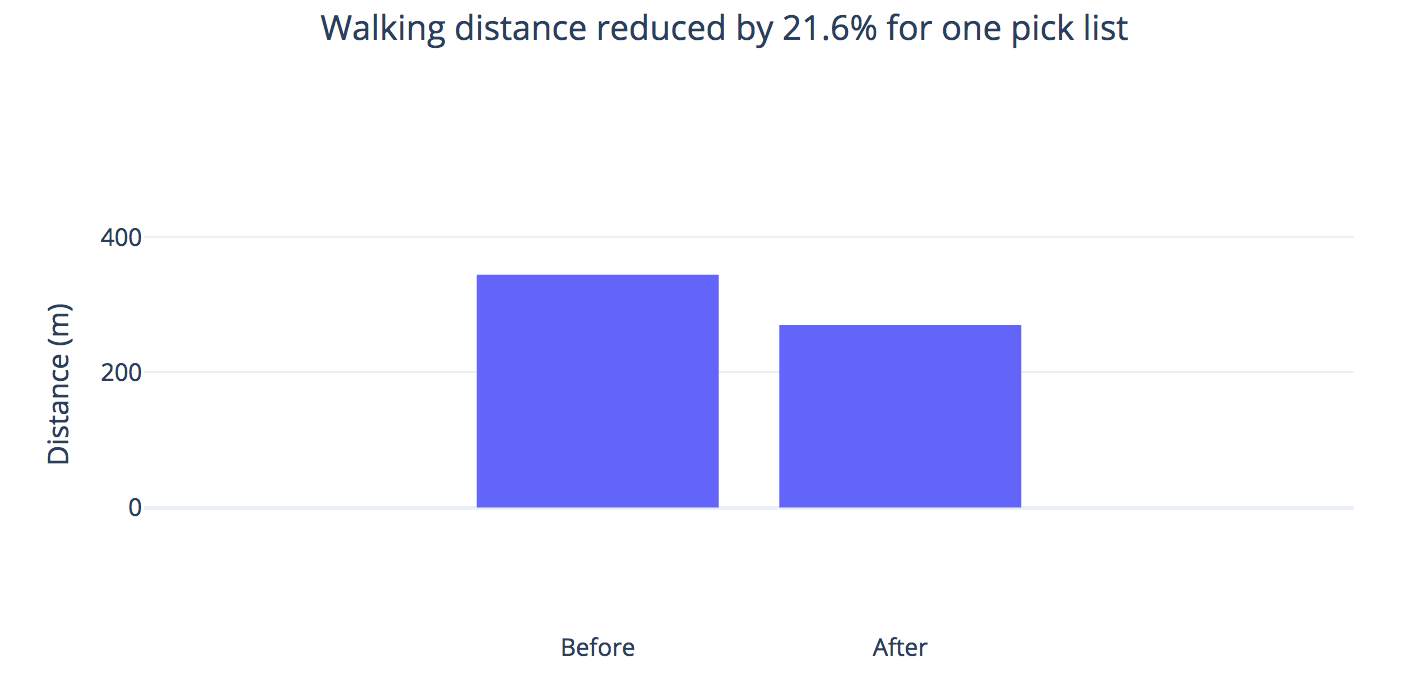

Whichever the method, there needs to be an efficient way to optimise order picking to reduce picker travel time across a warehouse. The IRIS Router was designed for that.

With the growth of e-Commerce, warehouse velocity and product variety (not forgetting the other 2Vs) will only increase and any form of heuristics developed through experience will naturally hit a glass ceiling. Leverage on algorithmic intelligence.

Why use the IRIS Router?

Produces an efficient picking path for a very large number of orders across a very large number of aisles for a decent number of cross-aisles

Estimates picking time for each order to monitor performance levels

Integrates with warehouse management systems

Able to efficiently route mobile robots in warehouses

Operational Benefits

Pickers walk through the shortest route (save time)

Intelligently route from the picker’s current location (save even more time)

Higher order picks per unit time (more productive)