Despite ongoing pressures to serve customers at the lowest possible price point, logistics service providers have a great opportunity to deliver high-value, customer-centric services while maintaining profitability in a commoditising industry. Labour is one of the single most significant expenses in warehouse operations and commoditisation aside, profitability is further affected due to rising labour costs.

Labour generally makes up 60–65% of the total cost of warehouse fulfillment.

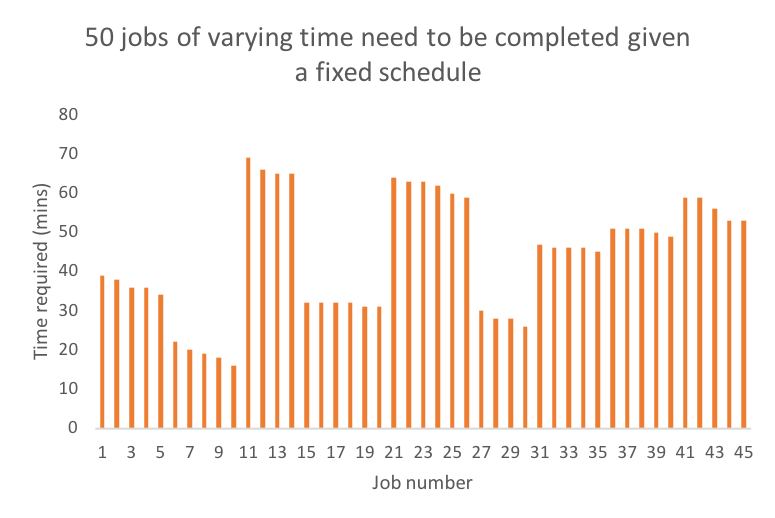

Being able to determine the number of people required for order fulfillment is integral to warehouse efficiency. This is especially so when picker-to-parts picking operations are generally labour dependent. Therefore, any increase in the total labour cost per worker raises the unit labour cost and correspondingly the cost per order. Manpower optimisation is needed to better manage costs arising from fluctuations, peaks and seasonality.

| Picker | Assigned job |

|---|---|

| 1 | 1 and 35 |

| 2 | 18, 41 and 45 |

| : | |

| 22 | 39 |

With the growth of e-Commerce, warehouse velocity and product variety (not forgetting the other 2Vs) will only increase and any form of heuristics developed through experience will naturally hit a glass ceiling. Leverage on algorithmic intelligence to better utilise manpower while maintaining service performance.

Why use the IRIS Manpower Optimiser?

Tells you how much manpower is actually required

Integrates with warehouse management systems

Operational Benefits

Pay only for the manpower required, and not more (save cost)

Redeploy manpower to areas where they will be better utilised (more productive)