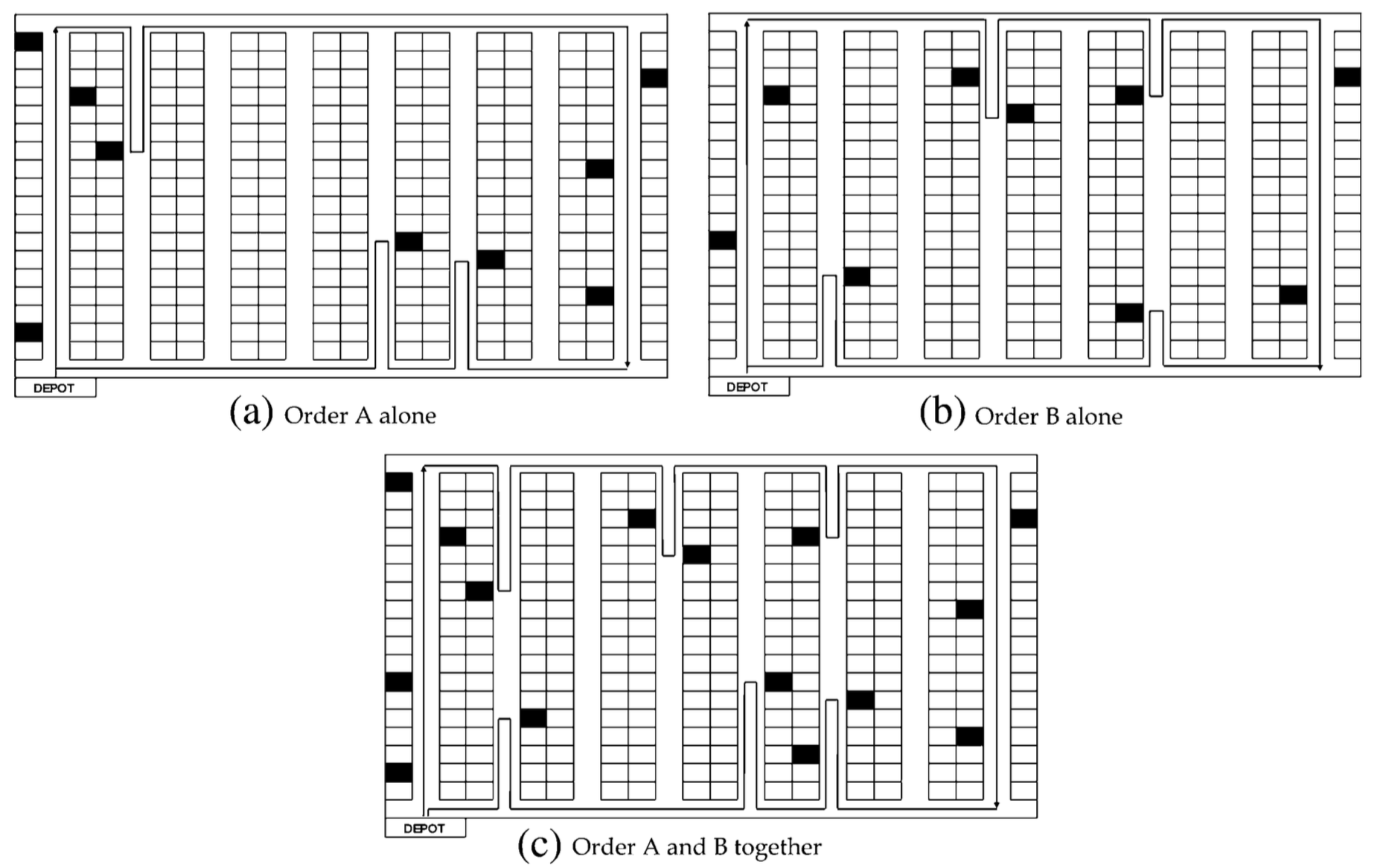

There are a number of routing strategies used in warehouses. The routing strategy determines the sequence in which the pick locations are visited and the efficiency of a routing strategy depends on the order profile, the storage strategy and the layout of the warehouse.

When routing strategies are coupled with batching strategies, this reduces the total picking time required to collect the requested items resulting in significant savings of labour cost and in a reduction of the customer order’s delivery lead time. Order batching has been proven to be pivotal for the efficiency of order picking operations.

Walking from one location to the next accounts for 60% of a picker’s time.

Batch picking can boost your pick rates from 60-70 lines an hour for single- order picking to 200 lines an hour or more, depending upon the order profile and the average cubic size of your orders.

| Strategy | Distance reduction |

|---|---|

| 1 | 63% - 80% |

| 2 | 61% - 84% |

With the growth of e-Commerce, warehouse velocity and product variety (not forgetting the other 2Vs) will only increase and any form of heuristics developed through experience will naturally hit a glass ceiling. Leverage on algorithmic intelligence to boost warehouse productivity.

Why use the IRIS BatchRouter?

Intelligently combines orders from multiple customers

Produces an efficient picking path for a very large number of orders across a very large number of aisles for a decent number of cross-aisles

Integrates with warehouse management systems

Operational Benefits

Pickers walk through the shortest route (save time)

Intelligently route from the picker’s current location (save even more time)

Higher order picks per unit time (more productive)